This will ensure the longevity and performance of the boiler, and the heating system generally, by protecting internal parts from corrosion and the build-up of scale over time. The whole aim is to prevent unscheduled interruption of essential services provided by the commercial boiler - namely heating and ready access to hot water.

In this blog post, Ideal Commercial shares the importance of protection and separation, as well as methods to ensure your boiler is running as efficiently as possible.

Why is Protection or Separation Needed?

Within the UK’s commercial heating industry, due to the maturity of the market, older open vented systems are relatively common. This can mean that there are pollutants in that system that present a risk to the new boilers. When retrofitting new boilers onto older buildings the main threat can be caused by the sludge and dirt that has accumulated in the system often as a result of oxygenation.

Within the boiler heat exchanger waterways, any contamination such as limescale, system dirt and magnetite can result in hard residue on the heat exchange surfaces. This can reduce the heat exchange capacity and impact the output of the boiler and therefore the whole system. Any reduction in the cross section of the boiler heat exchanger waterways, including potential blockages as a result of debris in the system, will present more resistance to system flow and can again affect the performance of the boiler and system. If the water is left untreated and the system circuit flows without treatment into the boiler circuit this can have a direct impact on the heat exchanger’s efficiency and lifespan.

Protection or separation is key to a boiler achieving its full potential, yet this can sometimes be taken out of tender proposals to reduce the initial installation cost. This is a potentially risky move when considering the long-term operation of the system. By advising on the potential long-term savings to an end user via system protection you can add value to your services.

Boiler System Protection and Separation Methods

To ensure that a boiler's longevity is maintained we encourage installers to consider system protection and separation. Doing this helps add protection to the internal parts from corrosion and sludge build-up over time. There are a number of methods that can be used to address this such as; filters or strainers, air and dirt separators, Low Loss Headers, Magnetic Low Loss Headers and Plate Heat Exchangers. Let’s take a look at how some of these methods work and their key benefits:

Low Loss Headers

By hydraulically separating the boiler from a secondary system, a Low Loss Header adds a huge benefit to an installation. The boiler can operate independently to a system where the load is likely to be variable and the operating range for the system may not be ideally suited to the boiler. For the boiler, if it was installed directly to the system pipework, a variable flow rate may lead to minimum flow rates for the boiler not being maintained. By keeping both systems separate, each side of the system can operate without disturbing the other. The boiler can provide as little or as much heat input as is required, and the system load can vary over a very wide range without affecting the boiler.

Not only can Low Loss Headers help the boiler and system to work well together, Low Loss Headers can help to preserve the working life of the boilers. As the flow rate through the Low Loss Header is very slow, it allows dirt or other particles to fall out of the flow. They then collect at the bottom of the low loss header for safe removal via a drain valve. In order to prevent any of the debris that settles being carried back through the boiler, Low Loss Headers are normally mounted vertically. Another approach would be the use of a Magnetic Low Loss Header which combines the benefits of a Low Loss Header with the addition of a magnet inside it, capturing the magnetite particles as well.

Plate Heat Exchangers

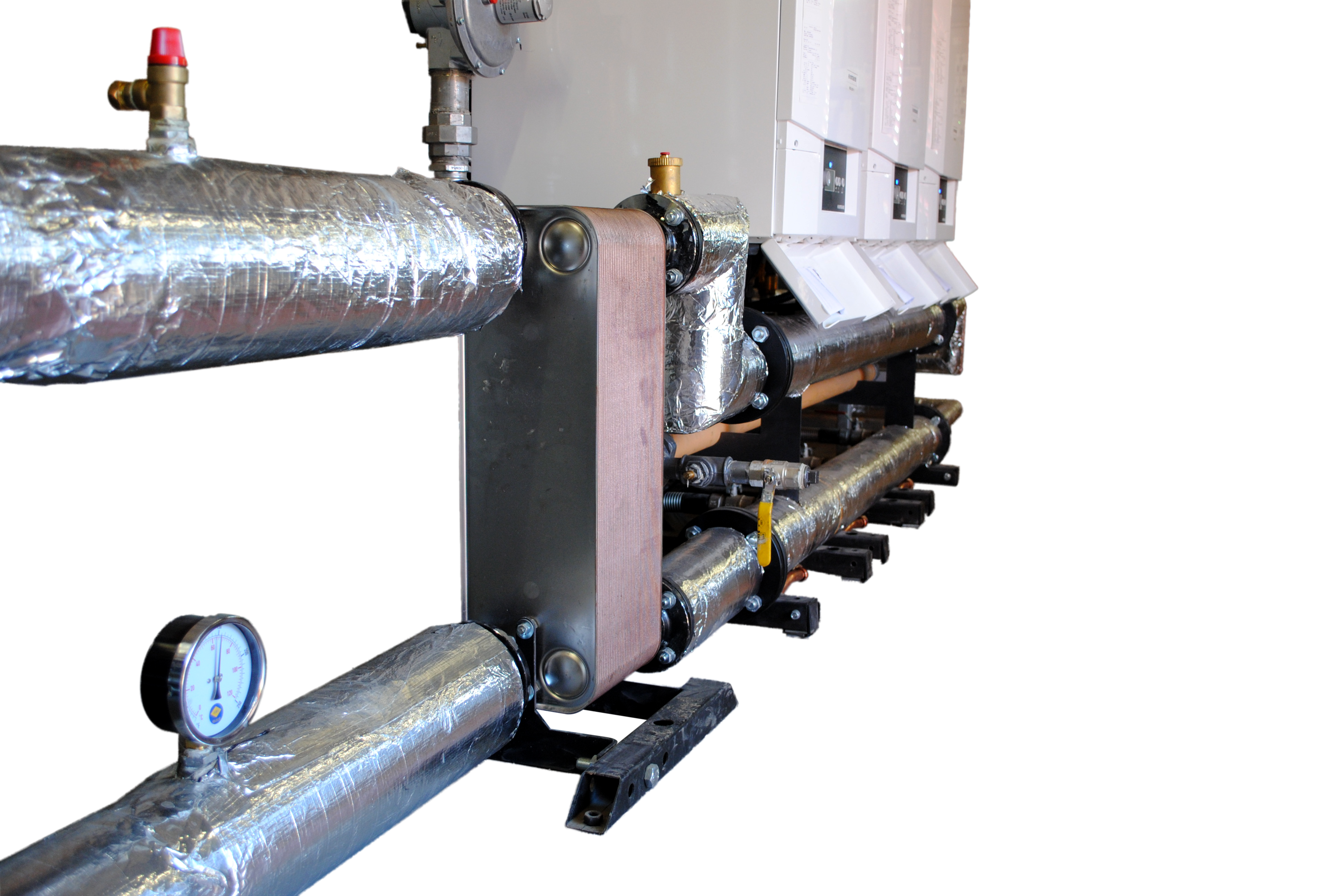

A Plate Heat Exchanger is another popular option for system separation. This method of separation works by transferring heat from the boiler circuit to the system circuit without the two circuits coming in direct contact; they are hydraulically separated by a pressure break with no mixing of the fluids in the different systems. The heat is transferred through a series of parallel plates with channels between them which the water can flow through independently of the other system.

Something to take into consideration when looking to install a Plate Heat Exchanger would be the heat transfer capacity and the temperature profiles on each side of the plate. These parameters will have a direct impact on how effectively the Plate Heat Exchanger will function, therefore the plate will need to be accurately sized prior to installation to achieve and maintain these parameters.

Plate Heat Exchangers are typically offered in two types: Gasketed and Brazed. Gasketed Plate Heat Exchangers comprise a series of plates fitted with elastomeric gaskets which are retained in a frame whereas Brazed Plate Heat Exchangers eliminate the gasketed joints, allowing for higher design pressures and temperatures.

The Importance of Water Treatment

Protection for boilers in any installation is considered to be good practice, and therefore the importance of maintaining water quality in the boiler circuit or the system circuit should not be forgotten.

Why is Boiler Water Treatment Required?

While protecting and separating the installation mechanically will help the boilers to reach their full potential, it makes sense to treat the water within the systems to ensure all parts of the installation are chemically protected as well. Protection and separation are crucial with retrofit installations in commercial settings; however they could be redundant if the water is left untreated.

The Water Treatment and Conditioning of Commercial Heating Systems Guide published by ICOM (Industrial and Commercial Energy Association), outlines the objectives of water treatment and pre-treatment to minimise the corrosion of system materials, to prevent the formation of mineral scale and prevent growth of microbiological organisms. Aimed at specifiers to maintenance contractors, it helps to identify best practice in water treatment.

What is Boiler Water Treatment?

Fresh untreated water used to initially fill a system can contain oxygen and other compounds that, if left untreated, would present a risk to the longevity and efficiency of the heating system. Cleansing the system prior to installation and suitable post-installation water treatment is considered good practice. The ICOM guidance recommends the use of dosing pots which provide a means to introduce liquid chemicals such corrosion inhibitors or biocides into closed systems. The guidance highlights that water treatment is needed across both circuits in the installation.

Obviously modern boilers and systems can comprise a number of different materials, so always seek the advice of a competent water treatment specialist to ensure that the appropriate chemicals in the correct concentrations are used.

Why is an Annual Boiler Service Important?

Engineers should encourage customers to get their boilers serviced by a Gas Safe registered engineer every 12 months. This will help to reduce the chance of any faults going missed whilst also protecting the commercial boiler and extending its longelifty. An engineer will be able to determine any work you need doing whilst also checking whether you require any water treatment or additional protection methods. Book your annual service today.

Helping Your Customers Make the Most of Their Commercial Boiler

The key thing to remember when planning and preparing any boiler installation is maximising the lifetime and efficiency of the boilers. System protection and separation using equipment such as Low Loss Headers, Magnetic Low Loss Headers and Plate Heat Exchangers will ensure that the boilers will work to their full potential along with ongoing water treatment.